Play Online Games on Nasution — Join the Fun!

Welcome to Nasution, the world’s top gaming site where endless fun and adventure are just a click away! Did you know that we offer more than 20,000+ games for players of all ages? Whether you're a young gamer or an adult looking for some exciting gameplay, we have something perfect for you. From engaging action-packed adventures to relaxing and creative puzzles, Nasution has it all.

We pride ourselves not only on our vast collection of games but also on the quality and safety of the gaming experience we provide. Every day, our team reviews and adds new games, ensuring that you're always presented with fresh and exciting content. You can count on us to offer a safe, enjoyable, and welcoming environment for everyone. Join the fun and explore the world of Nasution, where everyone finds something they love.

Games for Everyone – A World of Fun Awaits

At Nasution, we understand that every player has different tastes and interests. Whether you're into fast-paced racing, creative cooking, or classic strategy games, we have a wide array of categories for you to explore. Our game library is meticulously categorized to ensure that there’s something for everyone.

Fun Games for Girls: Get Creative and Play

For our female players, Nasution offers a delightful collection of cooking, baking, dress-up, and doll games that provide hours of entertainment. Whether you're an aspiring chef or a fashion enthusiast, our games are designed to spark creativity and let you indulge in the world of culinary arts and fashion.

In our cooking and baking games, you can experiment with various recipes, bake delicious cakes, prepare hearty meals, or run your own restaurant. These games are perfect for those who love to get hands-on in the kitchen and create delicious dishes.

Our dress-up and doll games are equally exciting for anyone passionate about fashion. Create your own unique looks with different outfits, hairstyles, and accessories, and become the ultimate stylist. If you love experimenting with colors, patterns, and textures, these games will provide endless hours of fun as you curate stylish outfits for your dolls or virtual models.

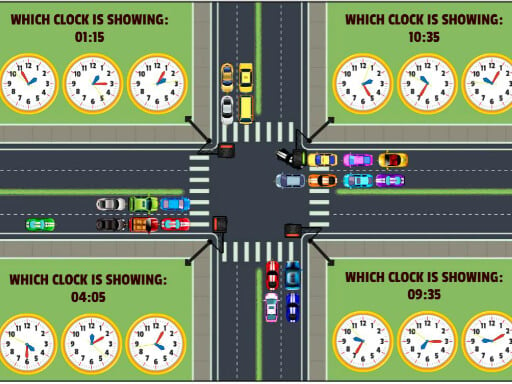

One of the most popular categories among female players is our picture gallery games, where you can challenge your memory and pattern recognition skills. These games involve matching images, identifying patterns, and solving fun puzzles, making them perfect for a quick mental workout or a relaxing break.